Specification

- Perforated basket or syphon basket;

- Visual access to the process area from the front door and inspection ports;

- Work cycle (from the loading phase to the discharge phase) where the operator cannot come in contact with the product;

- The centrifuge can work in the following operating modes, while it is controlled by PLC and DCS: fully automatic, semi-automatic, manual;

- Installation on concrete or carbon steel inertia base with anti-vibration dampers;

- Oil bearings lubrication for all models;

- Knife blade fixed without use of bolts;

- Installazione su base inerzia in cemento o acciaio al carbonio e tamponi antivibranti;

- Discharge even at maximum speed;

- The horizontal basket ensures a uniform load of the cake;

- Solids discharge via chute or screw conveyor;

- Complete removal of the residual heel cake via a nitrogen pressure system from the external part of the basket (“blow back”);

- The endless filter cloth, thermo-welded, in polypropylene or other tissues of various sizes and micrometrie, is easily replaceable;

- Materials in contact with the product: all stainless steels and special alloys available, such as AISI 316L, AISI 904L, Hastelloy, Monel, ALLOY 59, 254 SMO, NICKEL, TITANIUM, SAF 2205. HALAR coatings (ECTFE), also antistatic and FDA certificated, Teflon ETFE, HARD RUBBER;

Technical Data

| Centrifuge Model: HX | Basket Diameter | Filtering surface | Cake volume | Max load | Max speed | G factor | Weight with no motor | With inertia base and motor |

|---|---|---|---|---|---|---|---|---|

| Unit | mm | m² | dm³ | kg | RPM | xg | kg | kg |

| 500/150 | 500 | 0,24 | 15 | 19 | 2700 | 2037 | 650 | 1700 |

| 650/180 | 650 | 0,37 | 27 | 34 | 2400 | 2093 | 1400 | 3100 |

| 650/320 | 650 | 0,65 | 48 | 60 | 2400 | 2093 | 1550 | 3800 |

| 850/400 | 850 | 1,06 | 96 | 120 | 1900 | 1715 | 2750 | 6300 |

| 850/500 | 850 | 1,33 | 120 | 165 | 1900 | 1715 | 3200 | 7600 |

| 1000/500 | 1000 | 1,57 | 165 | 206 | 1550 | 1343 | 3600 | 12300 |

| 1000/650 | 1000 | 2,04 | 215 | 269 | 1550 | 1343 | 4200 | 12800 |

| 1250/650 | 1250 | 2,55 | 346 | 433 | 1300 | 1180 | 6500 | 16000 |

| 1300/850 | 1300 | 3,47 | 500 | 700 | 1250 | 1135 | 8500 | 21000 |

| 1700/920 | 1700 | 4,91 | 922 | 1290 | 1030 | 1000 | 14000 | 35500 |

| 1700/1150 | 1700 | 6,14 | 1152 | 1614 | 1030 | 1000 | 15500 | 42000 |

| 1850/1300 | 1850 | 7,55 | 1520 | 2130 | 985 | 1003 | 26000 | 58000 |

| 2000/1440 | 2010 | 9 | 2023 | 2832 | 950 | 1000 | 32500 | 70000 |

| 2100/1550 | 2100 | 10,2 | 2328 | 3260 | 900 | 950 | 33500 | 73000 |

Functioning

Production

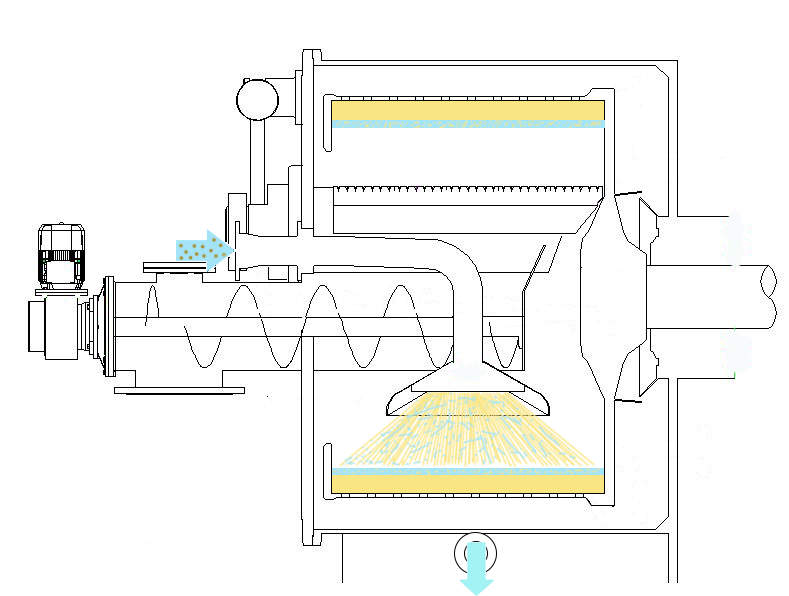

Loading

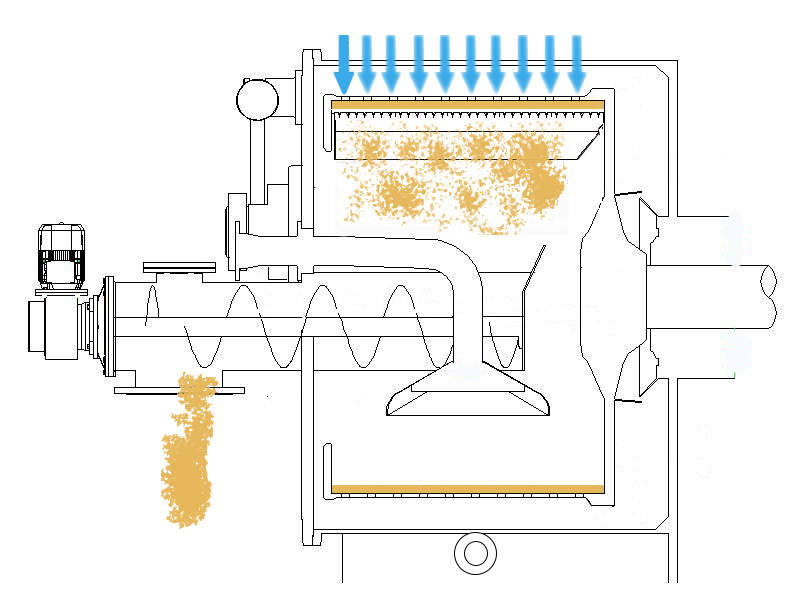

The solid-liquid suspension is fed from the feeding pipe into the centrifuge and under the influence of centrifugal force it moves towards the filter cloth, placed on a perforated basket. The solid part of the suspension is retained by the filter cloth forming a cake, while the liquid filters through the cake, the filter cloth and through the holes of the basket. The growth of the cake thickness is controlled by a mechanical or laser cake detector, which can automatically stop the feeding phase when the desired cake thickness is reached.

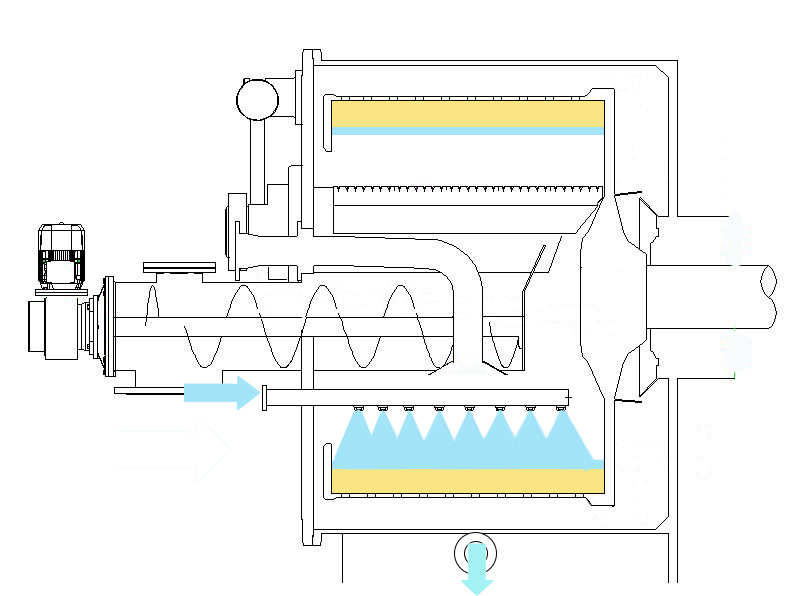

Cake washing

The washing of the product is used to remove any impurities present in the cake. The washing liquid is distributed on the product, along the entire length of the basket, through nozzles suitably distributed on the washing pipe. The liquid passes through the product, then passes from the filter cloth and the holes of the basket, removing impurity present in the cake.

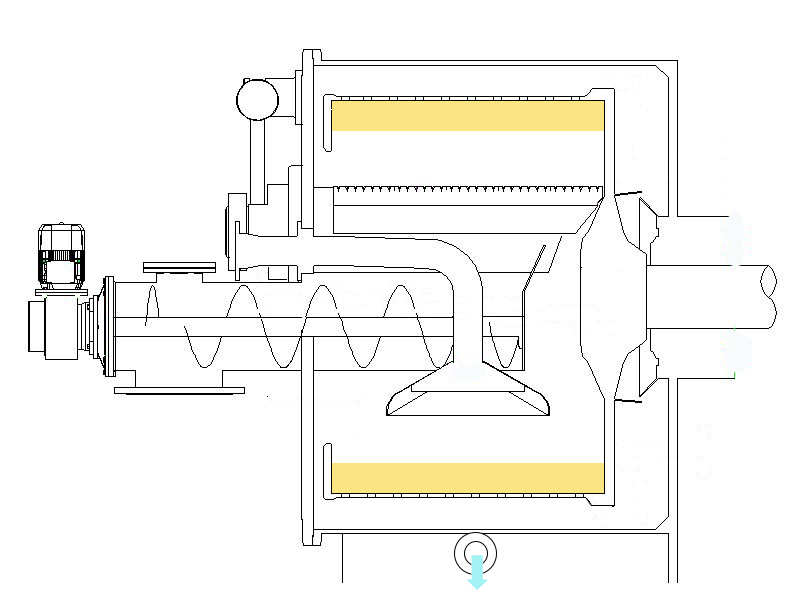

Centrifugation

Once completed the washing phase, the centrifuge is accelerated to the maximum speed and maintained for a given time to achieve the level of residual humidity of the product in processing. At the end of the centrifugation, the centrifuge decelerates to the discharge speed.

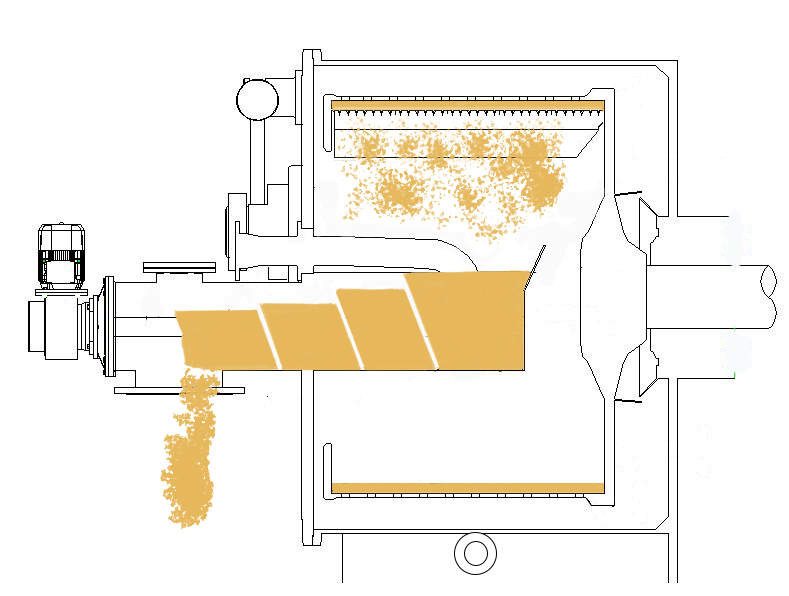

Discharge

The discharge takes place by means of the scraping knife. After reaching the discharge speed, the knife increment command is activated and the knife starts cutting the cake conveying the product into the discharge chute and from it to the product collection systems (drums, bin, dryers, mixers).

Heel cake removal

At the end of the product discharge phase, a heel cake of about 4÷5 mm remains on the filtering cloth. This heel cake can be removed, to improve the filterability of the product, through the high-pressure nitrogen blow from the rear part of the basket. The removed product is collected by the knife, positioned close to the filter cloth, and conveyed through the chute into the collection systems.

C.I.P.

The centrifuge should be cleaned at every change of product to avoid "cross-contamination" between the processed products. The centrifuge cleaning system, fully automated, is composed by 2 main stages: Washing Machine Effect and cleaning with spray balls, which can be alternated to achieve maximum cleaning and to optimize the consumption of the cleaning liquid.

Washing Machine Effect (WME)

The centrifuge is filled with the washing liquid up to a predetermined height and is put in rotation. During the sequence of the automatic washing the basket rotates clockwise and counterclockwise; the knife goes in and out so that the washing liquid reaches all the points of the process area, including the discharge chute.

Cleaning with spray ball

The washing liquid is sprayed through spray balls on all the surfaces of the process area to completely remove the residues of product still present.

Italiano (it-IT)

Italiano (it-IT)  Español (España)

Español (España)  Deutsch (Deutschland)

Deutsch (Deutschland)  Français (France)

Français (France)